How To Work Out What Strength Gas Struts You Need.

If you are replacing an existing gas struts the strength (N) should be printed on the strut you have. Otherwise…

The easiest way to guess the lifting weight required for a gas strut, is to use a set of bathroom scales, and length of timber.

Pick the position where you think the gas strut will be located and place the timber and scales there. This will show you the weight that is being applied in that position. If for example the scales read 20kgs then you need at least a 200N (20kgs x 10) strut to hold the weight.

Remember to take into consideration any extra weight such as a matress.

It is important to select the correct length of strut that will open to the desired height, but also allow the stroke to fully close.

Advanced: The Scientific Method.

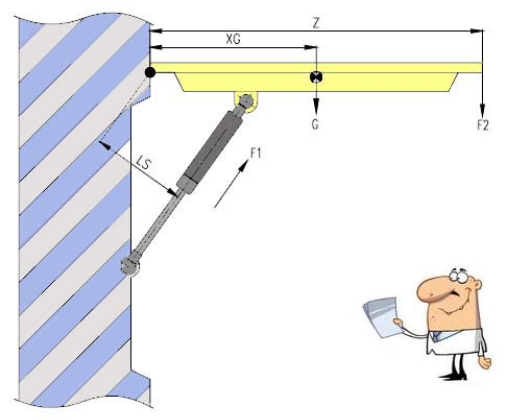

For those who would like to try a more mathematical approach to working out the strength then please study the formulas presented.

F1 = G x XG

F2 = A x F1 x LS

Z = length of lid from pivot (hinge) point in millimeters.

XG = Centre of Gravity in millimeters.

G = The weight of the lid in Newton. 1Kg is 9.8N (Round this to 10 Newton).

LS = Radius of Gas Spring Force in millimeters.

A = Number of gas springs per application. We recommend using two for most applications such as island beds

Gas Spring & Struts Mounting Instructions

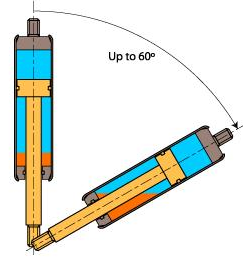

All gas springs contain a small amount of oil to lubricate the main seal and rod. This oil also provides end of stroke damping. If standard gas springs are operated and mounted in a rod-up orientation, fluid cannot reach the main seal or rod which leads to excessive seal wear and reduced life. It is recommended that standard gas springs be mounted rod down at least 30 degrees off horizontal. If the application cannot accommodate rod-down mounting, an oil or grease chamber should be specified. Both are optional features.

Why should springs be used rod-down ?

In order to keep the rod seal lubricated, a small amount of oil is used in every gas spring. When used rod-down, the oil is kept in contact with the rod seal which improves the sealing properties and ensure the seal will never become dry.

For this reason, one of the basic recommendations when incorporating gas springs in your design is to make sure they are used at an angle of less than 60 degrees from the vertical.

The oil used in the gas spring is also useful to obtain a high damping effect on the last few millimeters of the stroke. If the gas spring was not used rod-down, the piston would not have to go through the oil at the end of the extension and no damping effect would occur.

When this is not possible and the gas spring has to be used either rod-up or near horizontal, we specify an oil chamber or a fully damped gas spring. While these solutions are not as economical as standard gas springs, they will ensure your gas springs will last as long as a standard gas springs used with the rod facing down.

Find out all the gas struts what you need HERE.

Additional advice about the installation and removal of gas struts can be found by click here.